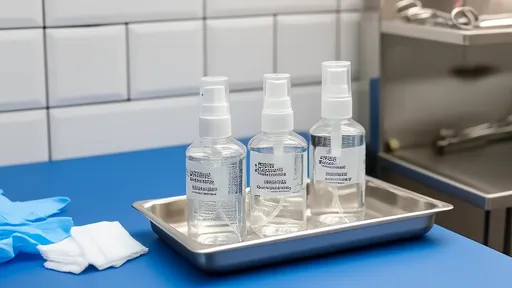

In recent years, the demand for effective disinfection solutions has surged, driven by heightened awareness of hygiene and infection control. Among the various products available, disinfectant wipes have gained popularity due to their convenience and versatility. While commercial options are widely accessible, many individuals and organizations are exploring the possibility of creating their own disinfectant wipes at home. This trend has led to a growing interest in DIY formulas for medical-grade disinfectant wipes.

The concept of homemade disinfectant wipes is not entirely new, but it has evolved significantly with advancements in understanding disinfectant chemistry. The primary goal is to replicate the efficacy of professionally manufactured wipes while ensuring safety and cost-effectiveness. However, it’s crucial to approach this endeavor with caution, as improper formulations can lead to ineffective disinfection or even damage to sensitive equipment.

Understanding the Basics of Disinfectant Wipes

Disinfectant wipes typically consist of two key components: a nonwoven fabric substrate and a disinfectant solution. The substrate must be durable enough to withstand scrubbing yet soft enough to avoid scratching surfaces. The disinfectant solution, on the other hand, must meet specific criteria to ensure it effectively kills pathogens without leaving harmful residues. For medical equipment disinfection, the stakes are even higher, as the wipes must comply with stringent health and safety standards.

The active ingredients in commercial disinfectant wipes often include quaternary ammonium compounds, hydrogen peroxide, or alcohol-based solutions. These ingredients are chosen for their broad-spectrum efficacy against bacteria, viruses, and fungi. When formulating a DIY version, it’s essential to select ingredients that offer similar antimicrobial properties while being safe for use on medical instruments.

Key Considerations for Homemade Disinfectant Wipes

One of the most critical aspects of creating homemade disinfectant wipes is ensuring the solution’s concentration is adequate for disinfection but not so strong that it causes corrosion or other damage. For example, isopropyl alcohol at a concentration of 70% is widely regarded as effective for killing most pathogens while evaporating quickly without leaving residues. However, higher concentrations can evaporate too rapidly, reducing contact time with microbes and diminishing effectiveness.

Another consideration is the compatibility of the disinfectant solution with the wipe material. Some fabrics may degrade when exposed to certain chemicals, leading to lint or fibers that can contaminate sensitive equipment. Nonwoven materials like spunlace or airlaid polyester are often recommended for their durability and resistance to chemical breakdown.

Potential Pitfalls and Safety Measures

While the idea of homemade disinfectant wipes may seem appealing, there are several potential pitfalls to avoid. For instance, mixing incompatible chemicals can produce toxic fumes or reduce the solution’s disinfecting properties. Additionally, improper storage can lead to evaporation of active ingredients or microbial contamination of the wipes themselves.

It’s also important to note that not all disinfectants are suitable for all types of medical equipment. Some materials, such as certain plastics or metals, may react adversely with specific chemicals. Always test the solution on a small, inconspicuous area before widespread use. Furthermore, homemade wipes may not meet regulatory standards required for clinical settings, so they should be used with caution in professional environments.

Exploring Alternative Formulas

For those seeking alternatives to alcohol-based solutions, hydrogen peroxide or diluted bleach (sodium hypochlorite) can be effective options. Hydrogen peroxide is particularly appealing because it breaks down into water and oxygen, leaving no harmful residues. However, it can be less stable over time, especially when exposed to light or heat. Diluted bleach solutions must be carefully measured to avoid excessive concentrations that could damage surfaces or pose health risks.

Essential oils like tea tree or thyme oil are sometimes suggested for their natural antimicrobial properties. While these can contribute to a wipe’s disinfecting capabilities, they should not be relied upon as the sole active ingredient, as their efficacy is often limited compared to synthetic disinfectants. Moreover, some essential oils can cause allergic reactions or skin irritation.

The Role of Proper Technique in Disinfection

Even the most well-formulated disinfectant wipes will be ineffective if not used correctly. Proper technique involves ensuring that the surface remains wet with the disinfectant for the required contact time—usually several minutes. Wiping too quickly or using insufficient solution can result in inadequate pathogen elimination. Additionally, surfaces should be pre-cleaned of visible dirt or debris, as organic matter can shield microbes from disinfectants.

For medical equipment disinfection, it’s also critical to consider the wipe’s texture and thickness. Wipes that are too thin may tear during use, while overly thick wipes can waste solution. Striking the right balance ensures efficient cleaning without unnecessary expense or frustration.

Final Thoughts on Homemade Disinfectant Wipes

Creating your own disinfectant wipes can be a rewarding project, offering customization and potential cost savings. However, it requires careful attention to detail and a thorough understanding of disinfectant chemistry. Always prioritize safety and efficacy, and when in doubt, consult professional guidelines or stick to commercially available products for critical applications like medical equipment disinfection.

As the world continues to grapple with infectious diseases, the importance of effective disinfection practices cannot be overstated. Whether you choose commercial wipes or opt for a DIY approach, the key is to stay informed and vigilant in your efforts to maintain a clean and safe environment.

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025